Hi,

I'm about to build my 3rd printer, even though I'm getting quite some experience already I'd like to hear some other advices regarding stepper motor.

I currently have a customized Prusa i3 printer and a customized Wilson II printer.

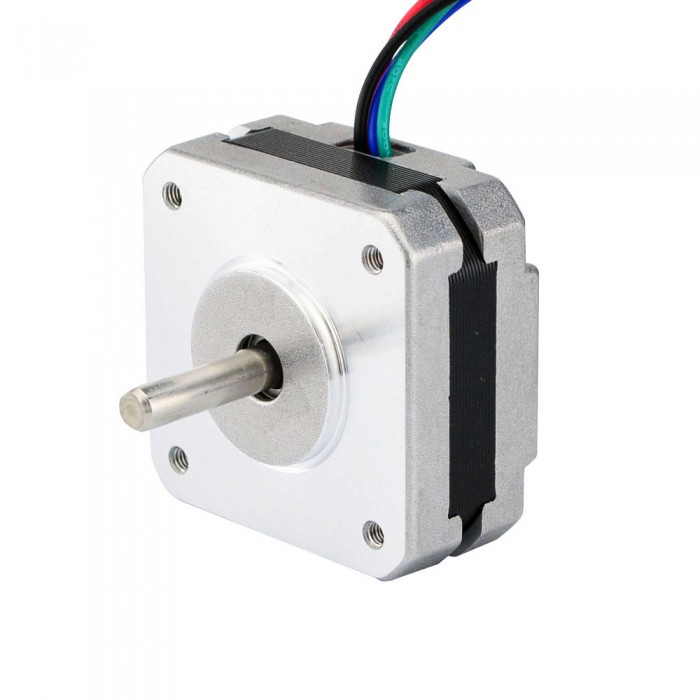

I currently run both printers with 0.9° step NEMA 17 motors (4200g.cm holding torque) for X and Y axis, I did run the i8 with 1.8° step NEMA 17 motors before, beside noise improvement I didn't see significant quality improvement.

I have make numerous experiments, and I have made the following observations

Microstepping seems to have very little influence on print quality at 1/4, 1/8, 1/16 or 1/32 microsteps @ 0.9° or 1/8, 1/16, 1/32 @ 1.8° below that noise and vibration will affect the print.

the belts have a high impact on print quality, Neoprene/glass fiber belts (standard black belts) give much more vibrations than Polyurethane/steel core belts (White belts), however the later might have other troubles due to their rigidity and tension force necessary, these are the one I use on the Wilson II but I had to strongly reinforce the structure.

I have made movement tests up to 400mm/s with the Wilson II and I didn't notice losing steps (1/8 microstepping with 0.9° motors)

Now my new printer will be a different design, it'll be a 40x40x40cm 100% metal structure cube, printing platform will be moving on the Z axis and X carriage will be moving along Y axis (I considered a corexy but rejected it). Since I expect much higher rigidity than my current printers and I might want to have a heavier carriage (converting to CNC maybe), I'm thinking about using NEMA23 motors.

I have options to go with 1.8 or 0.9° motors, I can get 23HS7628 1.8°/step motors with 18.9Kg.cm holding torque , 23HS5628 1.8°/step motors with 12.6Kg.cm holding torque or 23HM1430 0.9°/step motors with 18Kg.cm holding torque. I would use TB6600 drivers at max 1/16 microstepping.

Since motor prices are quite different, I'm curious to have a second opinion. I think the 0.9° will probably not bring any quality improvement since the limitation will still be mecanical, and anyway since the motors are much stronger than nema17 I can go further in useful microstepping. I can get a sweet deal on the 12.6Kg.cm motors, and I'm hesitating with the 18.9Kg.cm ones (1.8°) which are 50% more expensive.

Or... should I just stay with cheap Nema17 motors?

Any thought?