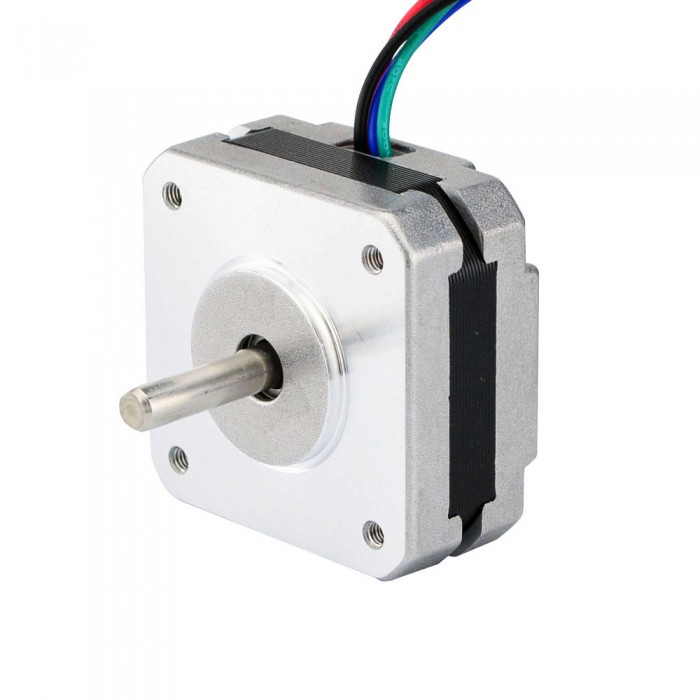

The first script presented below is written for controlling our bipolar stepper motor using the Parallax Basic Stamp 2 microcontroller and the Board of education, and is best suited for demonstrating the principle of stepper motor control, however other hardware can be used with appropriate electronic modules. The n

ema 34stepper motor is assumed to be connected on pins 1 to 4, and 3 buttons, for changing the direction and type of sequence, are employed.

' {$STAMP BS2}

' {$PBASIC 2.5}

pulsetime CON 25 //experiment with this value in ms

buttons PIN 13

button1 PIN 14

button2 PIN 15

driveanddir VAR Nib

sel VAR Bit

driveanddir=0

DO //main loop start

SELECT driveanddir

IF (buttons=0) THEN

sel=0

IF (button1=1) AND (button2=0) THEN

driveanddir=0

ENDIF

ELSEIF (buttons=0) THEN

sel=0

IF (button1=0) AND (button2=1) THEN

driveanddir=1

ENDIF

ELSEIF (buttons=1) THEN

sel=1

IF (button1=0) AND (button2=1) THEN

driveanddir=2

ENDIF

ELSEIF (buttons=1) THEN

sel=1

IF (button1=0) AND (button2=1) THEN

driveanddir=3

ENDIF

ENDIF

CASE 0 //wave drive clockwise

DO

driveanddir=0

HIGH 1

LOW 2

LOW 3

LOW 4

PAUSE pulsetime

LOW 1

HIGH 2

LOW 3

LOW 4

PAUSE pulsetime

LOW 1

LOW 2

HIGH 3

LOW 4

PAUSE pulsetime

LOW 1

LOW 2

LOW 3

HIGH 4

PAUSE pulsetime

LOOP UNTIL (button2=1) OR (sel=1)

CASE 1 //wave drive counterclockwise

DO

driveanddir=1

LOW 1

LOW 2

LOW 3

HIGH 4

PAUSE pulsetime

LOW 1

LOW 2

HIGH 3

LOW 4

PAUSE pulsetime

LOW 1

HIGH 2

LOW 3

LOW 4

PAUSE pulsetime

HIGH 1

LOW 2

LOW 3

LOW 4

PAUSE pulsetime

LOOP UNTIL (button1=1) OR (sel=1)

CASE 2 //wave drive clockwise

DO

driveanddir=2

HIGH 1

HIGH 2

LOW 3

LOW 4

PAUSE pulsetime

LOW 1

HIGH 2

HIGH 3

LOW 4

PAUSE pulsetime

LOW 1

LOW 2

HIGH 3

HIGH 4

PAUSE pulsetime

HIGH 1

LOW 2

LOW 3

HIGH 4

PAUSE pulsetime

LOOP UNTIL (button2=1) OR (sel=0)

CASE 3 //wave drive counterclockwise

DO

driveanddir=3

LOW 1

LOW 2

HIGH 3

HIGH 4

PAUSE pulsetime

LOW 1

HIGH 2

HIGH 3

LOW 4

PAUSE pulsetime

HIGH 1

HIGH 2

LOW 3

LOW 4

PAUSE pulsetime

HIGH 1

LOW 2

LOW 3

HIGH 4

PAUSE pulsetime

LOOP UNTIL (button1=1) OR (sel=0)

ENDSELECT

Another scripting example, written in C++, for controlling the motor by using the now defunct parallel port is presented below. In this script the

nema 42stepper motor is assumed to be connected on physical pins 2 to 5, or bits D0 to D3. A rapid example on how to calculate the output sent to the port:

Bit (pin)

D0 (2)

D1 (3)

D2 (4)

D3 (5)

D4 (6)

D5 (7)

D6 (8)

D7 (9)

Value (power of 2)

1

2

4

8

16

32

64

128

If you want to set a pin high, i.e. logic output 1, you need to send the corresponding value of the pin to the port. For instance for pin 5 the value to be sent is 8, for pin 3 the value is 2. If multiple pins are required to be set high, the sum of their corresponding values is sent tot the port. As an example, for pins 3 and 4 to be set high simultaneously, the value to be sent is 2+4=6, for pins 5 and 1 to be set high the value is 8+1=9.

#include

#include // ... all required libraries

#define PORT1o 0x378 //lpt output address -- check exact value in your settings

#define PORT1i PORT1o+1 //lpt input address

// ...... removed code used for defining variables and graphics drawing

//---functions defining control sequences for the motor, experiment with the delay value

void action1(void) // ---- wave drive clockwise

{

outportb(PORT1o,0);

outportb(PORT1o,1);

delay(50);

outportb(PORT1o,2);

delay(50);

outportb(PORT1o,4);

delay(50);

outportb(PORT1o,8);

};

void action2(void) // ---- wave drive conterclockwise

{

outportb(PORT1o,0);

outportb(PORT1o,8);

delay(500);

outportb(PORT1o,4);

delay(500);

outportb(PORT1o,2);

delay(500);

outportb(PORT1o,1);

};

void action3(void) // ---- full step clockwise

{

outportb(PORT1o,0);

outportb(PORT1o,3);

delay(500);

outportb(PORT1o,6);

delay(500);

outportb(PORT1o,12);

delay(500);

outportb(PORT1o,9);

};

void action4(void) // ---- full step counterclockwise

{

outportb(PORT1o,0);

outportb(PORT1o,9);

delay(500);

outportb(PORT1o,12);

delay(500);

outportb(PORT1o,6);

delay(500);

outportb(PORT1o,3);

};

// .... removed code

void main(void) // main program loop

{

// ... removed code

}

The parallel port in brief

In a few words, the parallel port was initially designed for connecting printers to a computer but using it as a general I/O port for communicating with various other devices was pretty straight-forward, especially since IEEE 1284 standard defined the bidirectional implementation of the port. A variety of USB-to-parallel adapters are still available, a selection can be found here.

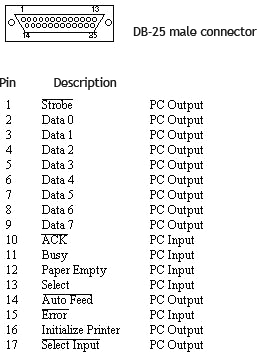

Parallel port DB-25 connector pinout

- The data register is located at IOBaseAddress+0 (e.g. 0x378, if the LPT port address is 0x378);

- The status register is located at IOBaseAddress+1 (e.g. 0x379) and can be accessed only through read operations;

- The control register is located at IOBaseAddress+2 (e.g. 0x37a) and can be accessed either through write or read operations.

The lines are bidirectional and bits 4 and 5 are for internal control of the parallel interface, bit 4 validates interrupts and bit 5 validates data register input.

See more:

http://forum.cncprovn.com/threads/3967-CKD-Suu-tam-Arduino-closed-loop-Stepper-motor?p=151859

https://forum.vellemanprojects.eu/t/how-to-calculate-linear-motion-mm-with-a-stepper-motor/9660